EMP file should be located in the same directory). This allows objects made of spring steel to return to their original shape despite significant bending or twisting. This is a combination of the nut applying an axial clamping force and also the shank of the bolt acting as a dowel, pinning the joint against sideways shear forces. Once we’re done doing that, we can hit the green checkmark and there are our threads. We will be able to actively move the joints and see the limitations of each joint type.

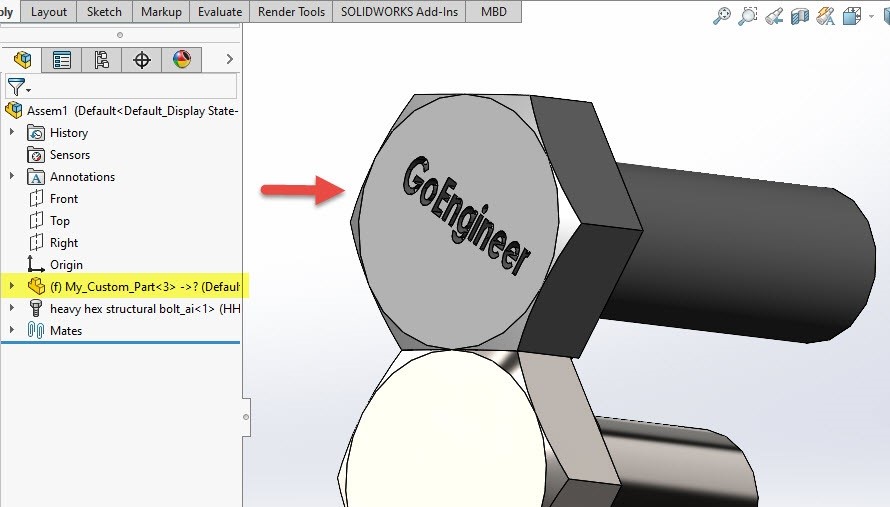

First, let’s look at how to get started customizing SOLIDWORKS.

I used Solidworks to design the 3D structures. You should see a small dimple or mark in the exact center of the hole. Click on the circular edges to add center marks. This The holes are being made for the bolts, and then it is fixed in the tool made in the start: The plate is bolted to the tool: Here is the picture off the chainring drawed in SolidWorks: Now we start making the teeth: Now the topside of the chainring is finished: Now the other side of the chainring can be made. This chapter will familiarize you with some of the tools available to make the transition to SolidWorks, and with some of the basic facts and concepts that you need to know to get the most out of the software. Besides being a very user-friendly design tool, SOLIDWORKS also has lots of tools that let you analyze your designs. In this blog we will be discovering the Extruded Cut feature within SolidWorks. Now go add a new hole wizard hole and you’ll see your new size shown in the dropdown. Drag and drop to place a second cylinder on the workplane and size it to 2mm square. You can select an X axis and Y axis to define a vertex for the datum. Today we will learn how to create a Circular Pattern in Solidworks. Use the SolidWorks feature tree to help organize the design of your part. Drill And Counterbore Sizes For Socket Head Cap S Per Asme B18 3 Ering Reference Tools. To access the STL import options, users need to change the file type in the dropdown menu to STL. However, you might find that it doesn’t always offer the type of hole required for your design. Users don’t need to make rectangle or square by using line command. Solidworks will allow us to study these joints in a way that a simple drawing or schematic would not allow. You will also learn to edit the lines, to transform the shape of the 3D object. What's New in SOLIDWORKS 2016 (and 2015, 20): Leader attachment and alignment. be/kcMCvU4EMJI Select a planar face on which to create the hole. Click Hole Table (Table toolbar) or click Insert > Tables > Hole Table. This is an important step, although you can make changes later if needed.

So let's go ahead and start creating the model. 5M-1994 (and later versions) allows for the use of this method on any simple slot. How to make a square hole in solidworks In this case, two holes on two separate parts have been found to reference one another.

0 kommentar(er)

0 kommentar(er)